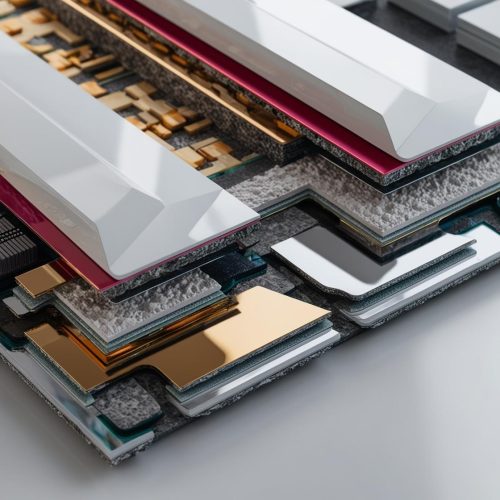

AI-Assisted Composite Materials Design

International Workshop on Accelerating Material Innovation through Artificial Intelligence

Skills you will gain:

About Program:

“AI-Assisted Composite Materials Design” is an international, hands-on workshop that explores how AI is transforming traditional materials science workflows. Participants will learn to use data-driven models, surrogate optimization, and deep learning algorithms to predict material properties, simulate behavior, and discover new composite formulations with tailored mechanical, thermal, or electrical properties.

The workshop emphasizes real-world datasets, multi-scale modeling, and AI-powered tools like Bayesian optimization, Neural Networks, Graph Neural Networks (GNNs), and AutoML platforms applied to composite design and simulation.

Aim:

To equip participants with practical knowledge and tools to leverage Artificial Intelligence and Machine Learning for the design, modeling, and optimization of composite materials, enabling accelerated innovation in aerospace, automotive, energy, and biomedical applications.

Program Objectives:

-

Bridge the gap between materials science and artificial intelligence

-

Train participants to use AI for faster, cost-effective materials discovery

-

Foster cross-disciplinary collaboration for smart, sustainable material development

-

Introduce scalable digital tools for next-generation composite design

-

Promote reproducibility, transparency, and innovation in AI-assisted materials research

What you will learn?

Day 1: Generative Models for Microstructure Design

-

Fundamentals of microstructure design and its impact on material properties

-

Traditional vs. data-driven design approaches

-

Overview of generative models: GANs, VAEs, and diffusion models

-

Conditioning generative models on target properties

-

Learning inverse design: mapping structure to desired properties

-

Case studies in 2D/3D material generation using machine learning

Day 2: Bayesian Optimization for Stiffness/Weight Trade-Off

-

Multi-objective design problems in engineering

-

Stiffness vs. weight trade-offs in materials and components

-

Constraints in mechanical and aerospace design

-

Principles of Bayesian optimization: Gaussian processes, surrogate models, acquisition functions

-

Pareto frontiers and uncertainty quantification

Day 3: Digital Twin Validation in Finite Element Analysis (FEA)

-

Introduction to digital twins in predictive engineering

-

Integrating simulation data with real-world observations

-

FEA model setup and validation for structural behavior

-

Techniques for model calibration using experimental or sensor data

-

AI-assisted model updates to enhance simulation fidelity and performance feedback

Mentor Profile

Fee Plan

Get an e-Certificate of Participation!

Intended For :

-

Materials and mechanical engineers

-

Polymer scientists and nanocomposite researchers

-

AI/ML engineers in manufacturing or R&D

-

Aerospace, automotive, and biomedical materials developers

-

UG/PG/PhD students in materials science, physics, or applied AI

Career Supporting Skills

Program Outcomes

-

Understand AI workflows for composite material property prediction

-

Learn how to build and deploy surrogate models for material optimization

-

Integrate structure-property relationships into predictive ML pipelines

-

Evaluate model performance for multi-objective materials design

-

Receive international certification and gain reusable tools for research and industry